How Greene Tweed Helped Brunswick Nuclear Power Plant Prolong their Water Pump’s Life

This is the second article in a series on Saltwater for Pumps. Read Part 1

Power plants, one of the largest water users globally, face a formidable challenge: the corrosive and abrasive threat of saltwater. From cooling systems to hydraulic operations, their critical pump components need to withstand the harsh seawater and brackish water environments.

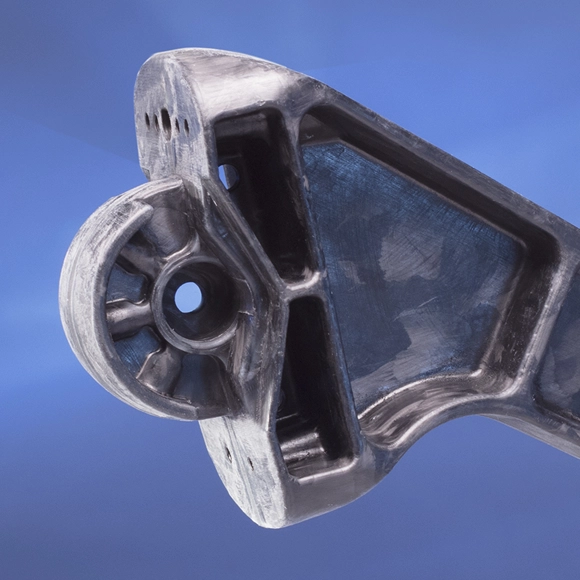

Consider Duke Energy, the operators of the North Carolina-based Brunswick nuclear power plant. Back in 2015, they were looking to replace eight Circulating Water Pumps (CWP) being used to pump high volumes of seawater. Duke Energy engineers needed to upgrade the bearing from cutlass rubber because of delamination issues. “Presence of saltwater containing salt, slit, and sand can damage the mating shaft, its sleeve, and the rubber cutlass bearings in circulating water pumps,” says Greg Gedney, industry expansion manager at Greene Tweed, who was working with Flowserve to support Brunswick nuclear plant.

An external flush provided to each of the composite bearing locations in the pump would trigger an alarm when the flush dropped below five gallons per minute of flow to the bearings. The low flush alarm was set to two minutes of low conditions prior to tripping the power to the pumps, causing significant problems. Gedney explains why: “This meant that if the bearing flush flow wasn’t restored within two minutes, the pump would shut down and disrupt the process. Additionally, frequent starting and stopping of the pump can be highly detrimental to its performance.”

To reduce the disruptions, the nuclear plant’s engineering team requested Flowserve, the pump’s original equipment manufacturer, to extend the low flow / flush alarm from two minutes to 15 minutes on the new pumps. The increased alarm to trip time on the new pumps meant that the bearings in the pump needed to survive a minimum of 15 minutes under low-flow conditions.

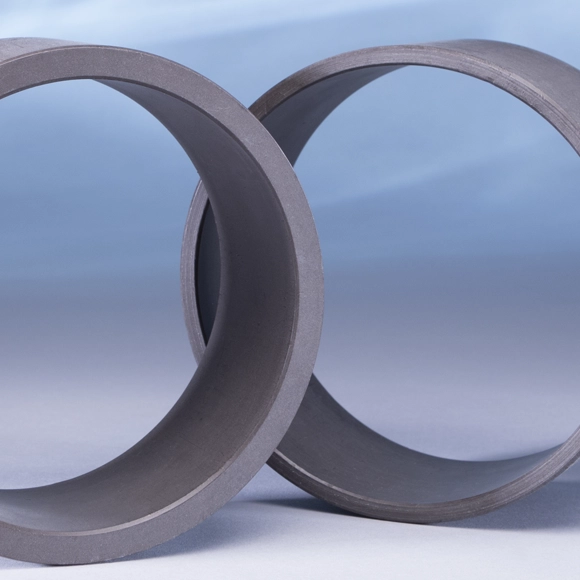

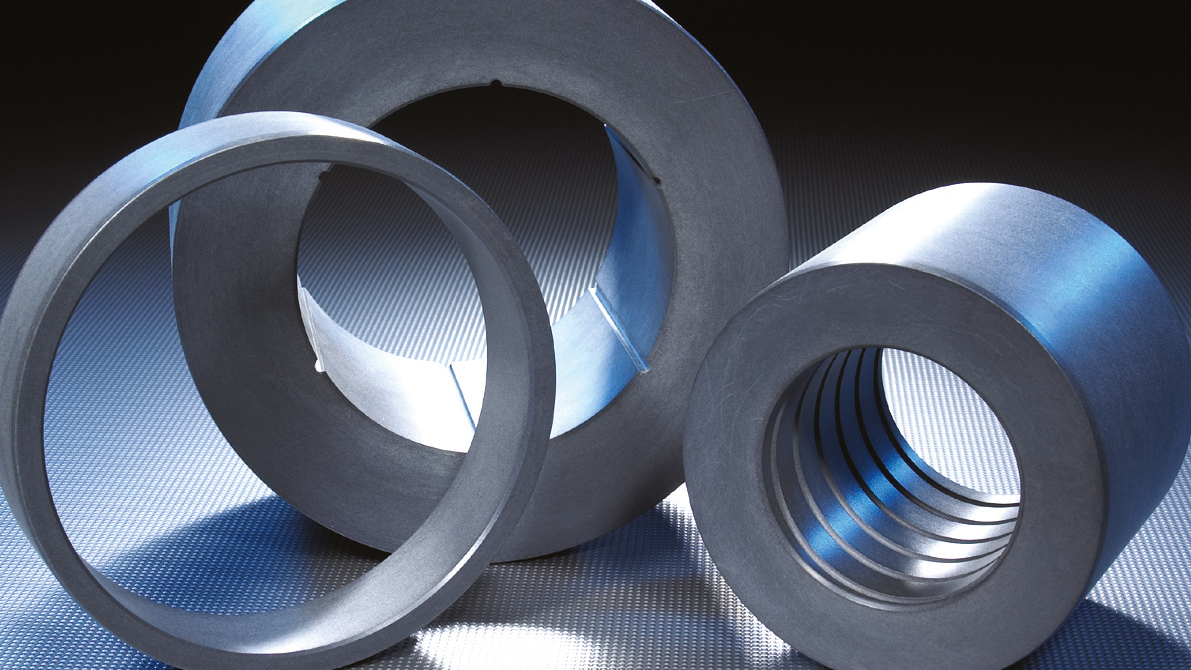

Flowserve reached out to Greene Tweed and our engineers proposed AR®-HT bearings, executing a bearing test program to validate AR®-HT composite bearings in an environment tougher than requested – totally dry conditions. Tests were performed with AR®-HT bearings and Stellite 12 shaft sleeves on the rotor, chosen due to their compatibility to saltwater and their surface hardness characteristics.

Greene Tweed’s AR®-HT bearings surpassed expectations, by resisting wear and maintaining running clearances, for longer than 105 minutes – compared to the original request of just 15 minutes – in dry run conditions without any lubrication. The pumps upgraded with AR®-HT bearings and Stellite 12 shaft sleeves, installed in 2016, have not required any significant maintenance since then. According to Duke Engineering, vibration levels are consistently low and smooth running. Since the bearing system is no longer the maintenance limiting factor of the CWPs, the preventive maintenance frequency is likely to extend beyond the planned 15 years,” says Gedney.

Encouraged by the results, Duke Brunswick plant engineers upgraded their service water pumps to the same combination: AR®-HT bearings and Stellite 12 sleeves. “Our bearings delivered once again and will now be used in the upcoming replacement of the circulating water ocean discharge pumps,” he adds.

Is your power plant or desalination unit facing similar challenges? Please reach out to a Greene Tweed representative to explore what our AR® (Abrasion Resistant) line can do to prolong your pumps’ life and reduce mean time between repairs.